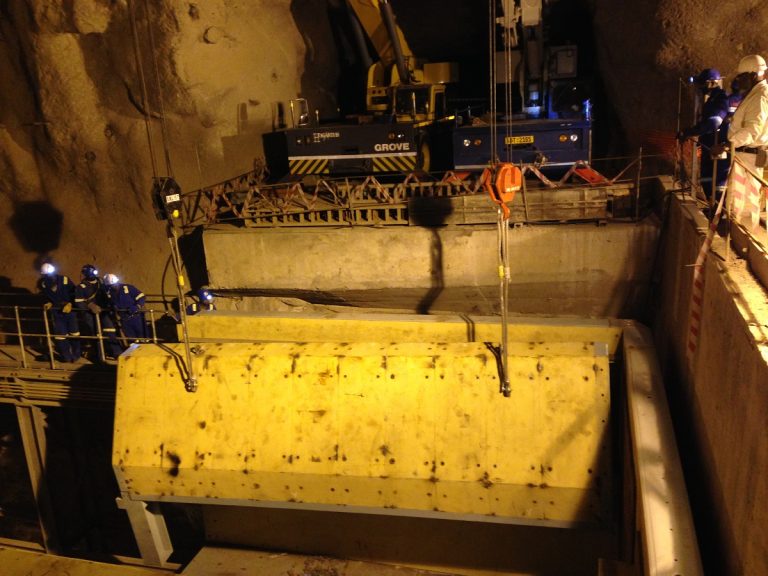

At the time, this project featured one of the few underground crushing stations in the world.

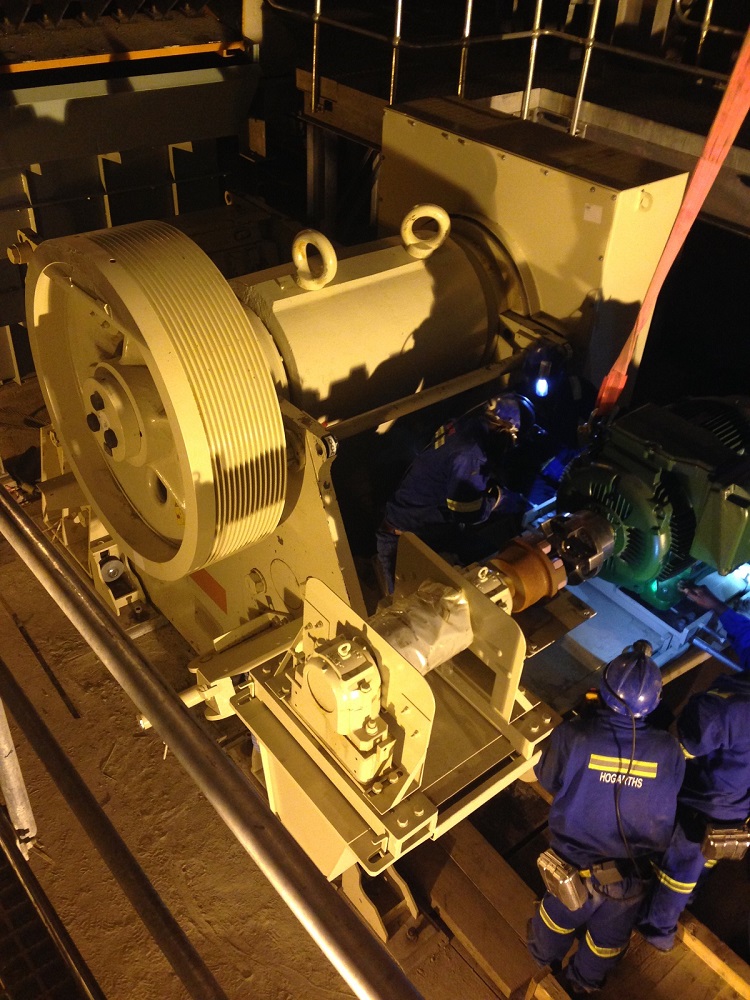

Hogarths was responsible for the fabrication and installation of steelwork, platework, and the installation of free-issue mechanicals. The project involved 250 tonnes of steelwork, 240 tonnes of platework, and 320 tonnes of mechanicals.

HDG steelwork was fabricated and delivered to the site by Viva Engineering, while painted finish platework was fabricated by Hogarths in its Bulawayo workshops.

Hogarths managed the erection and installation of all steelwork, platework, and free-issue mechanicals, ensuring the successful completion of the underground crushing station and conveyor system.